How MIG Arc Initiation Actually Works (And Why You Should Care)

You know what’s funny? Most welders can strike a perfect MIG arc in their sleep, but if you ask them exactly how that arc initiates, you’ll probably get a vague hand wave and something about “electricity doing its thing.” We’ve all been there.

Table of Contents

ToggleBut here’s the thing: understanding how arc initiation works in gas metal arc welding isn’t just nerdy physics talk. It actually matters when you’re troubleshooting those frustrating starts, choosing the right settings, or explaining to your procurement team why quality welding wire makes a difference.

So let’s break down what’s really happening in those first milliseconds when metal meets metal and magic happens.

The Short Circuit Secret

Here’s where MIG welding gets clever. Unlike TIG or stick welding that need high-voltage pulses to jump-start their arcs, MIG uses something called short-circuit transfer. Think of it as a controlled electrical handshake that happens about 100 times every second.

The process is surprisingly straightforward. Your wire feed pushes the electrode until it physically touches the base metal. That’s it. No dramatic sparks, no thousands of volts. Just metal touching metal.

What happens next is where physics gets interesting.

The Melt-Pinch-Ionize Dance

When that wire stub touches your workpiece, you’re suddenly completing an electrical circuit. Current rushes through (we’re talking 20 to 24 volts, nothing crazy), and because the contact point is tiny, all that energy concentrates into a small area. Heat builds fast.

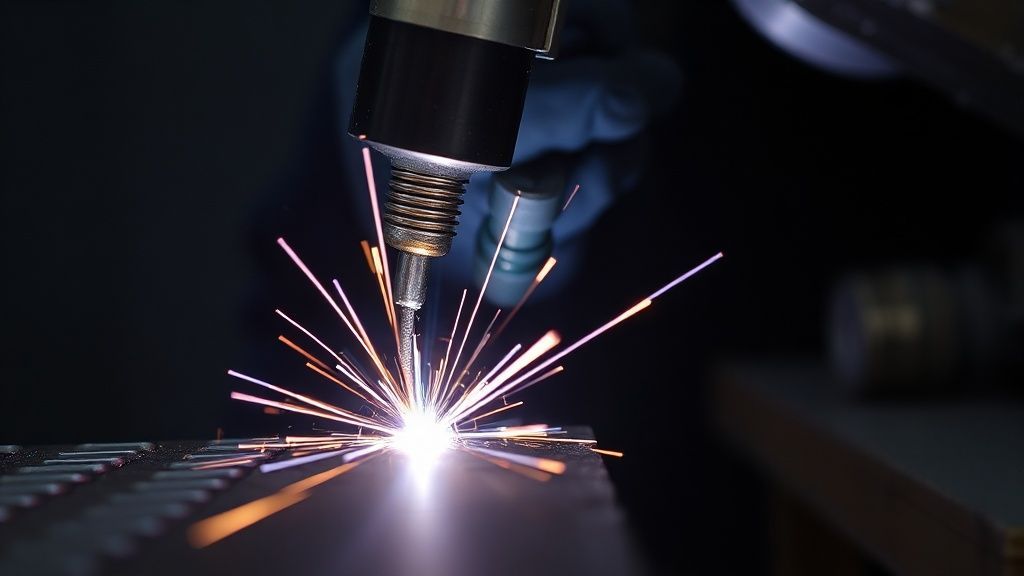

The wire tip melts almost instantly. But here’s the cool part: it doesn’t just drip off like candle wax. Electromagnetic forces squeeze that molten droplet, pinching it away from the wire. Picture an invisible hand flicking a water droplet off your finger, except this hand is made of magnetic fields.

As the droplet separates, a tiny gap forms. And in that gap? Your shielding gas suddenly becomes a conductor. The heat and electromagnetic field ionize the gas, creating a plasma channel that carries the arc. We’re talking about a gap smaller than one-eighth of an inch, but it’s enough.

Then the wire feeds forward again, touches down, and boom. The whole cycle repeats. One hundred times. Every. Single. Second.

Why Low Voltage Actually Works

If you’ve worked with other welding processes, you might be wondering: how does MIG initiate with such low voltage? TIG can need high-frequency pulses. Stick welding requires scratching or tapping. But MIG? Just 20 volts and you’re off to the races.

The secret lies in three factors working together:

The gap is ridiculously small. When you’re talking about distances measured in fractions of an inch, you don’t need massive voltage to jump across. It’s the difference between shouting across a room versus whispering to someone standing next to you.

Shielding gas lowers the breakdown threshold. That argon or CO2 mix you’re pumping through? It’s not just protecting the weld. It’s also making it easier for current to flow through the gap. The gas composition literally changes how easily electricity can ionize the space between wire and workpiece.

Continuous contact provides continuous opportunity. Since the wire keeps feeding and touching, you’re constantly resetting the initiation conditions. Miss one cycle? No problem. Another contact is coming in ten milliseconds.

What This Means for Your Welding

Understanding arc initiation isn’t just academic. It explains why certain problems happen and how to fix them.

Struggling with inconsistent starts? Your contact tip might be worn, changing that critical gap distance. Getting spatter during initiation? Your voltage might be slightly off, affecting how smoothly those droplets pinch away. Wire feeding feels erratic? The electromagnetic forces depend on consistent current, and poor connections throw everything off.

This is where wire quality enters the conversation. At Intiroda, we’ve spent years perfecting welding wire specifically because we understand these physics. Consistent diameter matters because it affects contact resistance. Surface quality matters because it influences how smoothly current flows. Copper coating thickness matters because it impacts the electromagnetic response during that pinch-off moment.

When you’re cycling through 100 arc initiations per second, even tiny inconsistencies multiply fast. That’s 6,000 opportunities per minute for something to go slightly wrong. Quality wire eliminates those variables.

Spray Transfer: The Plot Twist

Here’s something that trips people up: not all MIG welding uses this short-circuit initiation. Crank your voltage and current high enough, and you enter spray transfer mode. Instead of touching and separating, the wire starts ejecting droplets across a continuous arc. It’s like the difference between a dripping faucet and a steady stream.

But even spray transfer starts with that initial short circuit. You need that first contact to establish the arc. Once it’s going, the physics change, but the initiation? Still that same touch-melt-pinch sequence.

The Bottom Line

MIG arc initiation works through elegant simplicity: short-circuit transfer that repeats faster than you can blink. No high-frequency boxes. No scratch starts. Just continuous wire feed, low voltage, electromagnetic forces, and shielding gas working together in perfect rhythm.

Next time you squeeze that trigger and hear that satisfying crackle, you’ll know exactly what’s happening in those first milliseconds. Metal touching metal, current flowing, magnetic fields pinching, gas ionizing. One hundred perfect little handshakes every second, each one building the weld that holds everything together.

Want to know more about our products?

Explore the unique features and benefits of this product, designed to deliver exceptional performance and reliability. Unlock the potential it offers for your projects and see how it stands out in quality and value.